Features

Flexible Layout

· According to the size of the customer’s site, the inclined belt can be 20°, 28°, or 45°, the silo can be high or low frame, and the batching station can be arranged as ” 一” or “L” type, the loading ramp or flat loading is optional.

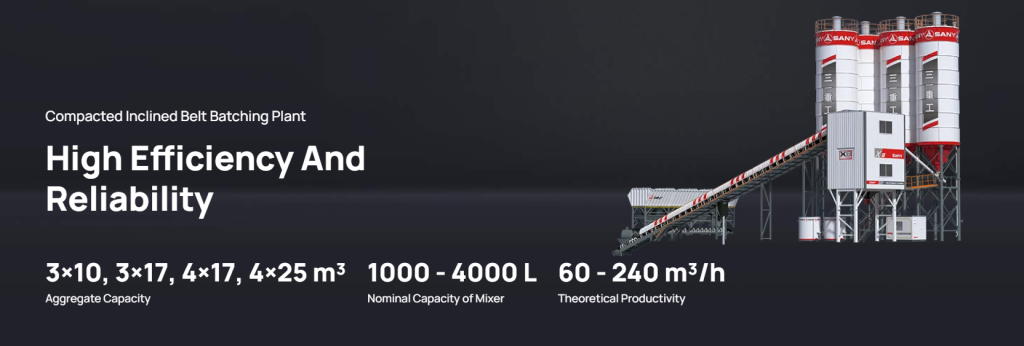

High Efficiency and Reliability

· Inclined belt batching plant has high efficiency and stability and low failure rate.

High Extensibility

· It can be used as a commercial batching plant and a project batching plant.

High-Performance Mixer, High-Efficiency Mixing

· Core patented shaft end sealing technology, automatic compensation, reliable sealing, easy maintenance with lower cost.

· Interrupted spiral arrangement of stirrer, large axial circulation, small radial circulation, central vortex stirring, three-way mixing and boiling type mixing, increasing efficiency by 20%.

· Optimal L/D ratio design, equipped with curved large opening discharge door, short discharge time, 3s less mixing time.

SYMC Controller, Safe and Reliable

· Multi-language operation interface

· Distributed network architecture or the entire control system with full digital transmission

· The upper computer and lower computer communicate through Ethernet, with a speed of 100000kbps

Adaptive Learning, Ensuring High Accuracy

· Multi-gear and multi-speed aggregates, adaptive adjustment of each weighing mode, and control curve

· Self-learning algorithm for weighing parameters, with automatic correction of dropout

· Self-learning water retaining advance, combined with jittering water retaining technology

Modular Design, Fast Installation and Disassembly

· Pre-installation of all electrical elements and pipelines, reducing the installation workload on site

· The main building is designed according to the standard container size, optimizing the maintenance space while occupying the least packing space.

Specs & Compare

| Models | Aggregate Capacity | Nominal Capacity of Mixer | Theoretical Productivity |

| HZS60X10 | 3×10 m³ | 1000 L | 60 m³/h |

| HZS90X8 | 3×17 m³ | 1500 L | 90 m³/h |

| HZS120X8Pro | 4×17 m³ | 2000 L | 120 m³/h |

| HZS180X8 | 4×25 m³ | 3000 L | 180 m³/h |

| HZS180C10H | 4×25 m³ | 3000 L | 180 m³/h |

| HZS240C10H | 4×25 m³ | 4000 L | 240 m³/h |

| HZS270C10H | 3×10 m³ | 4500 L | 270 m³/h |

Gallery